Stainless Band is a leader in processing stainless coil products in various forms, finishes, grades and dressings. With a turnover nearing £10m and over 35 employees, it is robust in a competitive sector. It has a global customer base that provides recognition and acceptance worldwide. Managing director Jonathan Hanson and his team certainly have something to smile about.

The volatility in stainless steel prices throughout 2023, marked by consistent increases, has been a notable trend in the industry. The anticipation of this trend persisting for some time, with a steady recovery projected for 2024, suggests a continuation of price fluctuations within the stainless steel market.

Up to 4% growth

The projection by the Bureau of International Recycling (BIR) indicating an expected growth of up to 4% in the stainless steel industry for 2024 is promising. This growth forecast hints at positive prospects and an upward trajectory for the industry, potentially driven by various factors such as increasing demand, global economic conditions, and market dynamics.

However, as Stainless Band knows, it is essential to consider that several variables, including raw material costs, supply chain disruptions, geopolitical factors, and shifts in global demand can influence the stainless steel market. These factors could impact the forecasted growth and pricing trends, making it crucial for Stainless Band to as always stay adaptable and responsive to market changes.

Supporting high-tech industries

Stainless Band plays a crucial role in supporting various high-technology industries, including the automotive, petrochemical, electronic, and pharmaceutical sectors. These industries have seen growth during 2023, contributing to Stainless Band’s expansion. Stainless Band’s emphasis on maintaining high standards of quality and unwavering dedication to exceptional customer service illustrates its commitment to excellence. Despite experiencing growth, Stainless Band prioritises maintaining the quality of its products and services and ensuring customer satisfaction.

Stainless Band’s global customer base, including the UK, Europe, the Middle East, USA, and Australia, demonstrates its global reach and international business operations. Regarding Brexit, Stainless Band has maintained a solid commitment to preserving a seamless customer experience despite the changes caused by the UK’s exit from the European Union. Importantly, Jonathan Hanson emphasises that customers are valued regardless of location. This customer-centric approach underscores Stainless Band’s dedication to providing consistent and high-quality services to all clients, irrespective of where they are.

Hanson’s perspective on Stainless Band’s success aligns with several key pillars:

High-quality product

The company’s commitment to delivering top-quality stainless steel products remains a fundamental factor in its success. It consistently meets or exceeds industry standards.

Flexibility and attention to detail

Being flexible and attentive to the most minor details enables Stainless Band to adapt to evolving customer needs.

Teamwork

Emphasising teamwork contributes to innovation, problem-solving, and overall company success.

Shortening supply chains

Streamlining supply chains leads to increased efficiency, reduced costs, and quicker response times, which are essential in meeting customer demands.

Focus on future growth

The company’s focus on expansion and investing in capabilities to meet evolving customer needs demonstrates its forward-thinking approach. This includes developing staff skills and integrating new processing capabilities.

Improving customer experience

Continual improvement in the customer experience is vital for retaining existing clients and attracting new ones.

By concentrating on these aspects, Stainless Band has established a robust foundation for sustainable growth, customer satisfaction, and maintaining a competitive edge in the stainless steel processing industry.

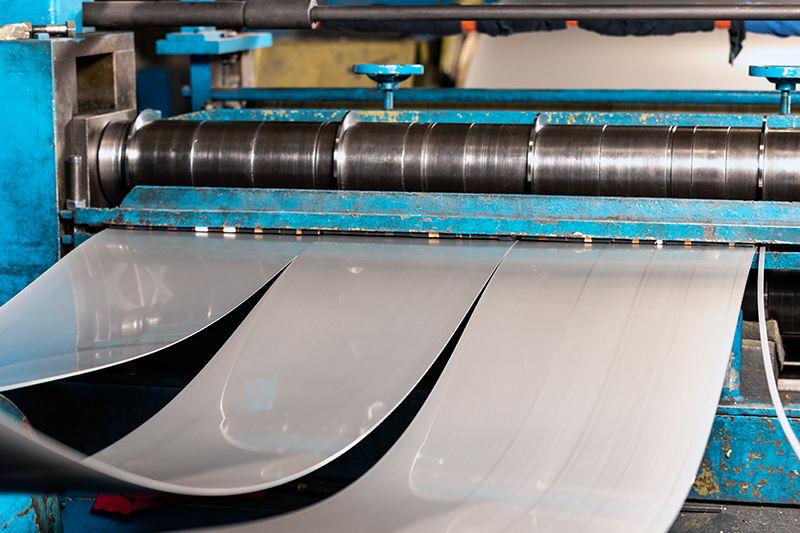

Hanson states, “We are proud to invest in our people and production machinery, which ensures that all product processing is on-site, guaranteeing quality and efficiency.”

Stainless Band’s plant list is continually expanding:

– 8 x slitters – capability width 2.50mm to 1,500mm wide, thicknesses 0.10mm to 3.20mm

– 1 x multi-spindle slitter/bobbin winder primarily designated for spiral wound gasket feedstock

– 4 x precision edge dressers capable of full round edge (E1) or deburred edges (E3)

– 1 x heavy oscillating spool winder, finished coil weights up to 1,000kg

– 1 x cut-to-length line 4 metres x 600mm x 3mm

– 1 x Jones 2 high rolling and flattening line

– 1 x polishing line

– 1 x oscillating spool winder from 0.50mm to 2.50mm, 1,000 kg coils

– X-ray analyser – thermo scientific

– NITON XL2 XRF for checking material grades and chemical analysis

– Mitutoyo Vickers hardness testing machine

– 1 x Mecmesin MultiTest 2.5-i (2.5 kN) tensile machine

Stainless Band’s comprehensive range of in-house services showcases its ability to cater to diverse customer requirements.

Each service offered plays a crucial role in enhancing productivity, reducing lead times, and maintaining a competitive pricing structure.

Stainless Band offers standard and precision slitting/shearing, temper rolled stainless steel, edge dressing, surface finishing, cut-to-length, oscillating/bobbin winding and slitting blanks and polishing.

Standard and precision

slitting/shearing

Providing both standard and precision slitting/shearing services allows for customising stainless steel coils into various widths, accurately meeting specific customer needs. Stainless Band offers a wide range of stainless steel grades to specification EN 10088-2:2014; large stocks of 304/316L/321/301 and 430/409 are held on-site.

Wide coil processing line

Adding a wide coil slitting line has been a great success for Stainless Band. It offers the capability for slitting up to 1,250mm wide coil x 0.20-1.50mm thickness in 304/316L/321 and 430/409. This unique line means the company can handle coils up to 8 tonnes on-site, reducing pricing and improving delivery times, another example of how its choice of investment is customer-centric.

Temper rolled stainless steel

Offering temper rolled stainless steel involves improving the material’s hardness, strength, and surface finish through controlled rolling processes, meeting clients’ precise specifications.

For temper rolling and flattening, Stainless Band operates a 2-high rolling mill in-house, producing temper rolled strips in the gauge range 0.60mm to 2.0mm in widths from 2.50mm to 120mm, in various hardness and tensile ranges. The in-house rolling facilities can flatten stainless steel strip to reduce cross camber or “D” section in the gauge range 1.00 to 3.00mm, and widths from 10mm to 110mm. The company can supply precision mill material for higher tensile over 1,000N/mm2 (330vpn).

Edge conditions

This service involves refining the edges of stainless steel coils, ensuring smoother, safer, and more precise edges, which can be critical in many applications.

Its edge rounding and dressing line eliminates the sharp edge, known as a burr, that occurs during the production of steel strips and coils. It can provide both small and large quantities of the stainless strips with various edge conditions. These range from standard material with a maximum burr of 5mm of the material thickness, to bevelled edges used for spiral wound gasket production with 90° angles, to fully rounded edges and flat rolled edges, which as well as improving product performance also reduces the risk of health and safety issues when handling sharp materials.

Slitting blanks and polishing

The capability to perform surface finishing on stainless steel ensures that the material meets particular texture, appearance, or corrosion resistance requirements.

Stainless Band can polish material in coil form or blanks, with material available in 120 to 320 grit finishes and thickness from 0.50mm to 3.00mm. It can supply sheet and cut blanks in the thickness range 0.50mm to 5mm, up to a maximum of 1,500mm wide, with cut blanks in the thickness range 0.50mm to 3mm, widths 10mm to 600mm, and lengths from 100mm to 4,000mm.

Boxed banding

Boxed banding refers to stainless steel banding in pre-cut lengths or rolls packaged in boxes for convenient handling, storage, and transport. These boxed banding products usually include stainless steel bands and accessories like buckles, clips, or tools required for installation and tightening. Stainless Band produces boxed banding in stainless steel and aluminium for the UK, USA and Canada.

Cut-to-length

Precise cutting to specific lengths as per customer specifications is crucial in various industries and applications, reducing waste and enhancing efficiency.

Oscillating/bobbin winding

Providing oscillating or bobbin winding services allows for customised packaging of stainless steel coils, catering to varied transportation and usage needs. Its oscillating wound capabilities incorporate a welding machine. The company can supply coils as large as 1,000kg, with the continuous strip welder on the oscillating line 0.40mm to 3.00mm, and 10mm to 80mm wide. By offering this material for the construction and automotive sectors, which are typical customers, machine output on pressing lines can be increased by 40% as the need to change coils is reduced.

Its bobbin wound precision strip is often used to manufacture spiral wound gaskets and other processes such as pressings. Stainless Band’s bobbin wound material is used extensively in the gasket sealing sector.

Bobbins can be up to 15kg, speed up the changeovers, and reduce scrap loss.

The size capabilities for spiral wound gasket production are:

– Thickness – 0.20mm; 0.18mm

– Width – standard sizes 5.33mm; 5.00mm; 4.75mm; minimum 2.50mm wide, 20kg minimum order quantity, depending on the grade

– Material supplied on plastic bobbins or as pancake coils.

Size capabilities for inner ring production are:

– Thickness – 3.00mm; 4.00mm; 5.00mm

– Width – from 6.50mm to 100mm

– 50kg minimum order quantity, depending on grade and thickness

– Material supplied as coil or in lengths of a maximum of three metres

– With bevelled edge condition to 90° angle.

Printed stainless steel strip

Printed stainless steel strip refers to stainless steel strips that have undergone a printing process to apply specific information onto the surface of the stainless steel material.

Ink jet

Employing digital technologies, Stainless Band prints onto the stainless steel strip.

Laser Printing/Engraving

Stainless Band uses lasers to etch or engrave designs onto the stainless steel surface, providing precise and permanent markings.

By having these services in-house, Stainless Band can effectively control and manage the production process, ensuring quality standards, meeting tight deadlines, and offering competitive prices. This integration also allows for more streamlined operations, reducing the reliance on third parties and enabling quicker response times to customer orders. Overall, these services contribute to Stainless Band’s ability to offer tailored solutions while maintaining efficiency and competitiveness in the market.

Hanson’s emphasis on fast order fulfilment and efficient shipment turnaround times meet customer needs promptly and reliably.

Several key points stand out:

Quick order processing

Shipping out most orders within seven to ten days is impressive when quantities range from 50kg to 2,500kg per shipment. This quick processing time is likely a significant factor in customer satisfaction and loyalty.

Varied shipment quantities

Catering to a wide range of shipment quantities demonstrates flexibility in meeting different customer demands. Whether it’s smaller quantities for specific needs or larger orders, Stainless Band’s capability to handle various shipment sizes contributes to its adaptability.

Investment in infrastructure

The investment in racking, picking, and storage facilities reflects a strategic move to streamline material flow within the company. This infrastructure investment has enhanced efficiency by optimising storage, facilitating quick access to materials, and ensuring smooth operations during order fulfilment.

Enhanced material flow

Stainless Band expedites processes, reduces lead times, and handles orders more efficiently by improving material flow through infrastructure investments.

The environment

And a thought for the future – Stainless Band remains dedicated to investing in its machining processes, aiming to enhance sustainability continually.

Its unwavering commitment lies in minimising the environmental footprint generated by its activities. So all in all a positive outlook for Stainless Band and its existing and future customers.