The decision to set up a turned parts subcontracting business at the start of the worst economic crisis in living memory has paid dividends for Yian Stavrou and George Dingley, joint owners of Luton-based Sub-CNC Precision (www.sub-cncprecision.co.uk). Supporting their successful evolution from earning a few thousand pounds a month in 2008 to turning over a predicted £3 million in the company’s current financial year has been, from the very beginning, continued investment in twin-spindle, multi-axis, bar-fed lathes supplied by Citizen Machinery UK (www.citizenmachinery.co.uk).

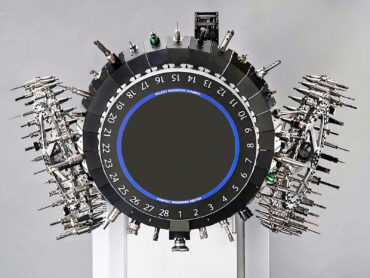

Over the years, the ISO 9001:2015-accredited and JOSCAR-registered subcontractor has bought 25 of them, part exchanging a few to leave 21 on the shop floor as of November 2025. Two-thirds are Cincom sliding-head models for producing parts from 0.5 mm to 38 mm in diameter and the remainder are Miyano fixed-head turning centres. Many of the lathes run around the clock, lights-out from 6.00 pm to 7.00 am.

In total, there are 27 CNC machine tools on the shop floor, including another fixed-head turning centre, three vertical machining centres with 4th axis, a CNC cylindrical grinding machine and a 3D printer. The list of industries served is long, including aerospace and defence, automotive and motorsport, telecommunications, sensors, energy and renewables, hydraulics, medical and instrumentation.

The introduction of Citizen’s proprietary LFV (low frequency vibration) chip-breaking software in the Cincom control massively assisted unattended machining, according to Yian. He said, “In 2017, we installed one of the first LFV machines in the country, a 20 mm bar capacity L20-VIII which arrived in the April, followed at the end of that year by a 12 mm capacity L12-VII.

“It was immediately clear that their ability to break what would normally be stringy swarf, which would necessitate stopping the machines to clear it away manually, into short chips meant we could leave them unattended to produce components, even from difficult-to-machine materials, knowing that we would arrive in the morning to a bin full of perfect parts. It is the only way to remain competitive in the face of competition from low-wage countries.”

The two lathes were immediately deployed onto turn-milling parts from copper and phosphor bronze, during which LFV’s effectiveness at chip-breaking the long, continuous coils of swarf was especially apparent. Monel, Inconel, titanium alloys and other exotics including for submarine component manufacture were similarly machined reliably. Encouraged by this initial success, Yian and George have made sure that no new Cincom since then has entered their factory without LFV. Currently, more than half of the sliding-head lathes on the shop floor are equipped with the function.

!function(e,t,n,c,r,a,i){e.Newsletter2GoTrackingObject=r,e[r]=e[r]||function(){(e[r].q=e[r].q||[]).push(arguments)},e[r].l=1*new Date,a=t.createElement(n),i=t.getElementsByTagName(n)[0],a.async=1,a.src=c,i.parentNode.insertBefore(a,i)}(window,document,"script","https://static.newsletter2go.com/utils.js","n2g");var config = {"container": {"type": "div","class": "","style": ""},"row": {"type": "div","class": "","style": "margin-top: 15px;"},"columnLeft": {"type": "div","class": "","style": ""},"columnRight": {"type": "div","class": "","style": ""},"label": {"type": "label","class": "","style": ""}};n2g('create', 't5up6a9j-uwzoraoj-lbg');n2g('subscribe:createForm', config);